Audit It. Improve It! Getting the most from your vibration monitoring program – by Alan Friedman

Buy it on Amazon.com: Audit it Improve it Buy the electronic version here

Are you getting the most from your vibration monitoring program? Is your program compliant with ISO and other standards? Does your program conform to industry recognized best practices? Are you getting the return on investment you deserve? If you are uncertain or answered “no” to any of the above, then this book is for you. Alan Friedman takes you step by step through an easy to understand process of auditing and improving your vibration monitoring program. Now you can benefit from Alan’s 24+ years of experience in setting up and supporting such programs. Chock full of tips and tricks and easy to understand worksheets to get you started, Audit it Improve it is a must read for anyone involved in maintenance or condition monitoring.

Buy it on Amazon.com: Audit it Improve it Buy the electronic version here

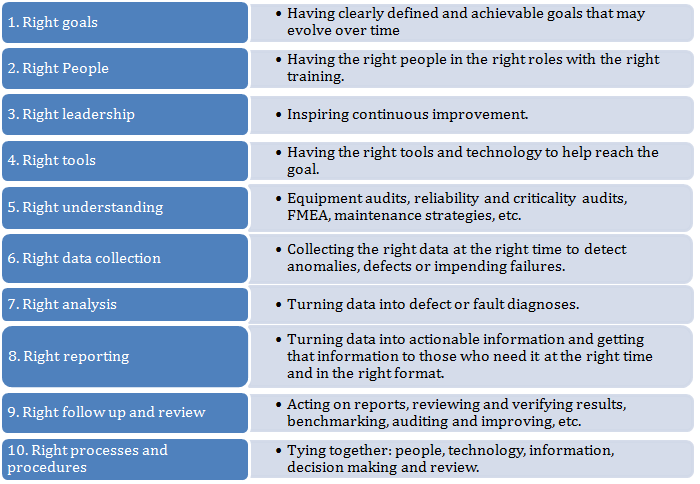

10 Components of a Successful Program

The book walks you step by step through each of these main areas to make sure your program is up to snuff. Vibration monitoring is about more than just taking measurements and reading graphs, it is about changing how the plant makes important repair decisions. Making these decisions in an intelligent way requires not only good information but the correct processes and procedures to make sure that information gets into the hands of those who need it and that they use the information to their best advantage. A world class condition monitoring program is about all of the elements listed above.

Audit It Improve It!: Buy it on Amazon.com: Audit it Improve it Buy the electronic version here

ISO 55000 and ISO 9001

There is a worldwide movement towards compliance with management and reliability standards such as ISO 55000 and ISO 9001. It makes good business sense to be certain that you plant is not only in compliance but that it follows best practices. Improved reliability results in fewer accidents, injuries, environmental disasters and the lawsuits associated with them. Improved reliability also results in higher production and lower unit costs making your plant more competitive in the market place. The bottom line is that reliability makes sense.

Audit It. Improve It! Getting the most from your vibration monitoring program – by Alan Friedman will help you to determine if your condition monitoring program, a key component of any reliability strategy, meets industry best practices and is in compliance with international standards. Not only will the book help you reap the greatest rewards from your program, it will also help you determine if it is compliant. The book references key standards related to condition monitoring and vibration analysis from The International Standards Organization (ISO), American Petroleum Institute (API), International Electrotechnical Commission (IEC) and the Hydraulic Institute (HI). Easy to understand “Auditors Checklists” help you to determine where your program is and is not compliant.

Buy it on Amazon.com: Audit it Improve it Buy the electronic version here

Most programs fail

Most programs fail to reach their potential and some programs fail entirely. One reason for this is a gap in the training that is typically available. Certification courses teach about the technology and how it works. They are necessary to make sure that individuals meet minimum standards of knowledge and capability. They are also useful to be sure the plant is in compliance with standards. Equipment vendor training typically focuses on how to press the buttons on the data collector or how to use the software. The subject that is typically not taught is how to run and manage a large program over a long period of time; how to measure if that program is successful from a technical and financial point of view and how to keep the program running as personnel come and go. These are the topics covered in the book and these are the skills that Alan can help you with during on-site training and program reviews.

Buy it on Amazon.com: Audit it Improve it Buy the electronic version here

If you have read this book, please leave your comments below. If you have requests for new content or questions, please email them to zencovibe@gmail.com

Audit It Improve It! Table of Contents

1. Introduction 4

2. Using This Book 6

3. Main Components of a Condition Monitoring Program 9

4. Running a Successful Program 12

5. Why Condition Monitoring Programs Fail 15

6. Setting Goals for Your Condition Monitoring Program 23

7. Ways to Use Vibration Analysis 34

8. Tips for Solving Problems 45

9. Understanding Key Performance Indicators 59

10. Personnel and Training 66

11. Understanding the Machine 77

12. Proactive Maintenance 83

13. Documenting Machine Information 89

14. Data Collection 102

15. Database Configuration 108

16. Setting Alarms and Baselines 115

17. Analysis Procedure 135

18. Report Generation 147

19. Follow-Up and Review 155

20. Wrapping It Up 165

21. Conclusion 167

Appendix A: Glossary 170

Appendix B: Summary of Standards 178

Mechanical Vibration and Shock 178

Balancing 178

Mechanical Vibration of Machinery Alarm Limits 178

Condition Monitoring and Diagnostics of Machines 179

Training and Certification of Personnel 180

Acceptance Testing 180